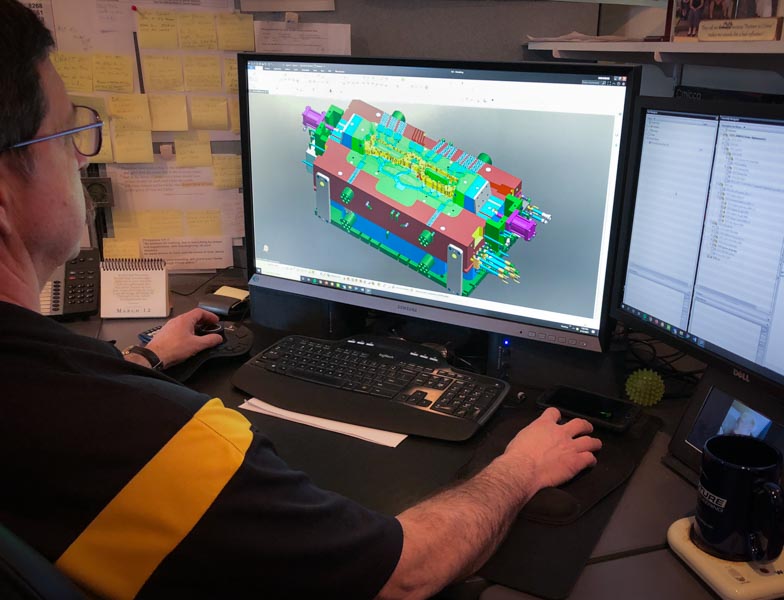

From product design to completed mold, our engineering team has the experience to handle multiple complex projects. Our product design utilizes NX2007. Our customer service is supported by our skilled engineering staff, which specializes in full 100% 3D designs and complete 3D solid modeling.

Project Engineering

Our project engineering team has over 75 years combined experience. You can be confident their knowledge and expertise will result in robust tooling to meet your needs as well as the quality requirements of your customer.

Project Engineering Details

General Die & Engineering’s objective is to provide 100% satisfaction with 100% on time delivery. We provide detail-oriented program management to insure not only the best Quality of our product but also ensure our customer’s needs are fulfilled. Our internal metrics show we have achieved on time delivery of 99.9% for the past 36 months and 100% for the past 27 months.

General Die & Engineering’s objective is to provide 100% satisfaction with 100% on time delivery. We provide detail-oriented program management to insure not only the best Quality of our product but also ensure our customer’s needs are fulfilled. Our internal metrics show we have achieved on time delivery of 99.9% for the past 36 months and 100% for the past 27 months.

Project engineering tools we use include:

- New tool Kick-off meetings to review the scope of work, customer tooling needs and standards.

- Design & Engineering check sheets at three different levels to ensure customer requirements are followed, Action items logs are reviewed so build questions are resolved in a timely manner.

- A Mold build plan detailing customer expectation is developed with descriptive build requirements for each department.

- CMM “Metrology” check requirements are developed with the customer to ensure all critical features are controlled and checked.

- A detailed Mold Check List is completed by the tool maker and reviewed by the Forman & Program manager at the end of the build prior to shipment. We encourage our customer to inspect their tools with us prior to delivery.

- Any non-compliant issues will be corrected prior to shipment or shipped with the customer’s authorization.

- Any defect would then be corrected after first sample during the first progression of the tool.

- Program management personnel will attend meetings with the customer as well as aid at the tool First run at a sample facility or customer’s facility.

- We use an internal machining schedule “MS Project Master Timeline” for all CNC machines including any sub-contractors if needed.

- Microsoft Project is used for planning and tracking all tool builds detailing Engineering, to all operation in the cavities, building of the mold base, to final assembly.

- The dedication of our management team here at General Die & Engineering guarantee’s our employees know our customers’ expectations and strive to make sure that they are met.

Project Engineering Contacts

Our engineering staff is ready to quote your tooling needs.

Whether it's a single tool or an entire tooling package, GDE has the experience you need.

Troy Monroe, Engineering Manager

- Engineering Design

- Data Management

Phone (616) 871-1454

Curt Herrington, Program Manager

- Die Cast

- Plastic Injection

- Global-sourced Tooling

Phone (616) 871-1467

John Perry, Program Manager

- Die Cast

- Coining Dies

- Aerospace - Hot Form

Phone (616) 871-1448

CAD / Design

Our design team has an average of over 16 years experience in tool design and modeling. Working entirely in full 3D solid modeling gives our designers the ability to clearly articulate design concepts, issues or problems, as well as their solutions.

CAD / Design Details

Engineering & Technology

General Die & Engineering is completely committed to providing only the finest quality molds and dies. On-time deliveries result from project management systems that track your mold throughout the design and manufacturing process. Customer service is supported by our skilled engineering staff, which specializes in 100% full 3D designs and customer problem solving. Starting with full 3D designs and then creating files for the CNC machines, allows us to build the mold from engineering.

General Die & Engineering is completely committed to providing only the finest quality molds and dies. On-time deliveries result from project management systems that track your mold throughout the design and manufacturing process. Customer service is supported by our skilled engineering staff, which specializes in 100% full 3D designs and customer problem solving. Starting with full 3D designs and then creating files for the CNC machines, allows us to build the mold from engineering.

General Die & Engineering uses the following Application Software for Cad

- Die Design NX1973 & Moldwizard (back support to NX 7.5)

- Data Translation Parasolids, Step, TransMagic (for native Catia), IGES

- Support Systems VISI 2023 with TST Ram EDM, WorkNC 2023, Actify-Spinfire

From Product Design to completed mold, our Engineering team has the experience to handle multiple complex projects.

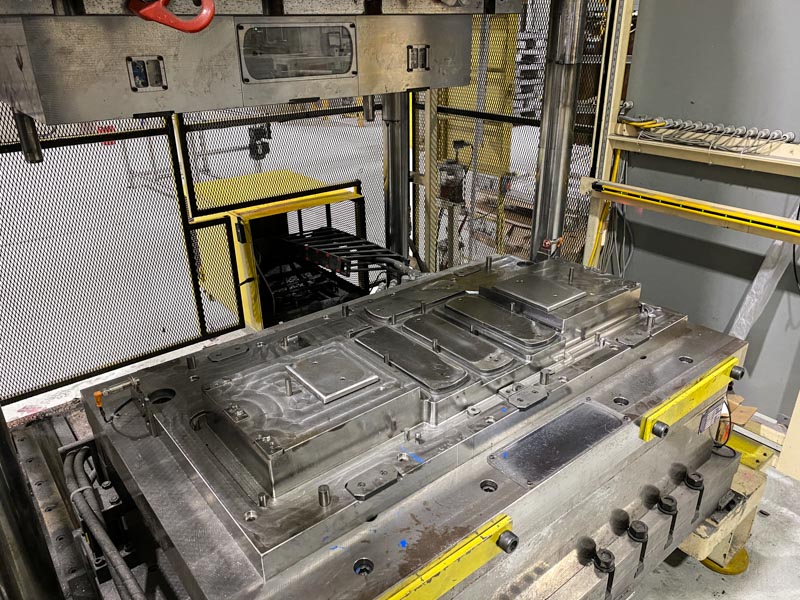

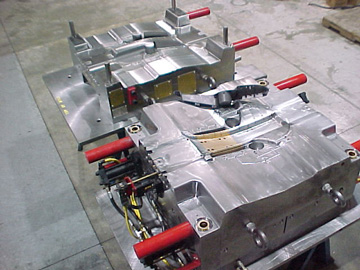

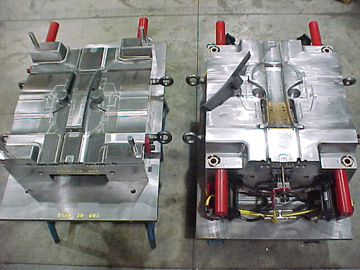

Plastic Injection Molds

Specializing in highly visible parts both interior and exterior. Widely known for building difficult injection molds with multiple actions and diamond finished cavities. One of the foundations of our multi faceted tooling service we offer here at General Die & Engineering.

Plastic Injection Mold Details

Regardless of the size or complexity of your part, we have the capability and experience to build your tooling. Whether it's a large fender liner or small intricate mold, simple open/close or multiple slides/lifter/retractors, General Die & Engineering can supply you with the robust tooling that your production requirements demand.

Rear wheel liner mold

Rear wheel liner mold

Rear wheel liner mold

Rear wheel liner mold

Cup holder armrest

Cup holder armrest

Cup holder armrest

Cup holder armrest

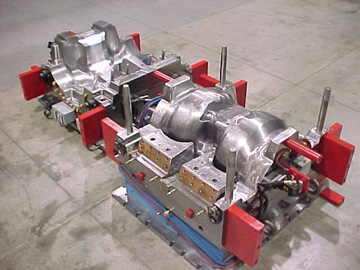

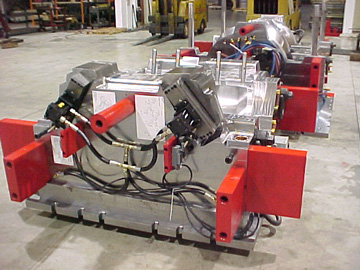

Die Cast Dies

Specializing in magnesium and aluminum die cast dies built to your specifications and standards. GDE has long been an industry leader, fulfilling todays timing and quality needs to meet expectations in making lighter and more fuel efficient cars of tomorrow.

Die Cast Die Details

2010 Pace Award Winning Die Design

2010 Pace Award Winning Die Design

General Die & Engineering has always been, and continues to be, on the leading edge of the die cast tooling industry.

With today's deadlines getting shorter and shorter, you need a tooling supplier who can deliver a robust quality tool in more compressed timeframes. General Die & Engineering has a long history of meeting and exceeding our customers expectations in that regard. Our quality system allows us to record and track any and all changes during the tool build process, to insure your tool meets your precise expectations. Our knowledgeable engineering and design staff are ready to take your data and their experience to design a tool that meets your standards, in a timely fashion.

Industry First

In 2003, General Die & Engineering was the industry leader in designing and building the first 2 cavity die cast magnesium instrument panel tool in the world.

In 2003, General Die & Engineering was the industry leader in designing and building the first 2 cavity die cast magnesium instrument panel tool in the world.

Largest Dies

The magnesium tailgate inner is the largest die cast magnesium closure panel globally. It not only saves substantial weight but it also functions as the primary structural load carrying component of the liftgate assembly meeting stringent crash performance requirements, integrates six separate parts into one inner panel casting, allows for increased passenger headroom, is 100% recyclable and meets the acceptance criteria for Class A die cast surfaces.

In 2008 we designed and built another first. This time it was a liftgate. The entire part cast in a single tool, just one of our challenges was to overcome 3 million pounds of shot pressure in a self locking tool.

In 2008 we designed and built another first. This time it was a liftgate. The entire part cast in a single tool, just one of our challenges was to overcome 3 million pounds of shot pressure in a self locking tool.

Giga Press Tooling

Always looking toward the future, General Die & Engineering is investing resources in tooling for the Giga Press. Giga Press die casting is the most recent advance in aluminum die casting. Currently, Tesla has invested in four Giga Press machines manufactured by IDRA Group for their Model Y automobile.

These massive die casting machines range in size from 5,600 ton to 8,000 ton. They are the largest high pressure die casting machines in the world. A single machine weighs almost 1 million pounds. These machines take a 180 pound shot of molten aluminum and cycle into a complete part in 90 seconds. A single machine can produce 1,000 aluminum die casting per day. (source: Wikipedia)

Die Casting Machine #2 (DCM2) Giga Press during assembly at Tesla Factory in Fremont. The open space in the middle between the compression plattens holds the die casting mold halves, and separates apart to allow removal of the completed casting using a robot.

Die Casting Machine #2 (DCM2) Giga Press during assembly at Tesla Factory in Fremont. The open space in the middle between the compression plattens holds the die casting mold halves, and separates apart to allow removal of the completed casting using a robot.

Photo Credit: Gabeincal, CC BY 3.0, via Wikimedia Commons

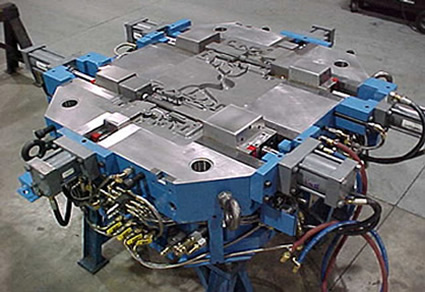

Die Cast Coining/Straightening Dies

General Die & Engineering is the domestic industry leader with the most experience, 8-years, in building coining/straightening dies for the die cast structural industry.

Coining Die Details

One-directional with no actions

Multi-directional with actions

General Die and Engineering is the domestic industry leader with the most experience, 8-years, in design, engineering, and manufacturing coining/straightening dies for the die cast structural industry.

Coining/straightening dies play an essential role in precision structural die casting to realign parts back to net or near net shape. They are needed to overcome warp issues that occur during the casting process or after parts been stress relieved or heat treated.