At General Die & Engineering, quality runs much deeper than just inspection. Checks, inspection, validation, metrology, and reports are integral to our process. We check everything, as it's being designed, engineered, and manufactured, and again before delivery to our valued clients. We deliver quality you can count on.

The centerpiece of our validation is our precision measuring equipment, the Zeiss PSM Coordinate Measuring Machine, CMM, and the Kreon Ace Measuring Arm wtih Skyline 3D Scanner.

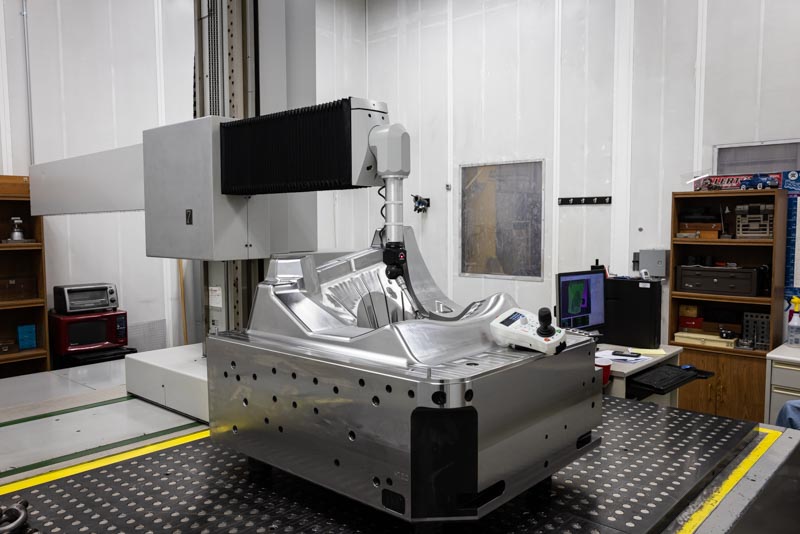

Zeiss Model PSM Horizontal Arm Coordinate Measuring Machine

Zeiss PSM Horizontal Arm CMM, equipped with Metrolog X4 Software and FCS fixturing.

Zeiss PSM Horizontal Arm CMM, equipped with Metrolog X4 Software and FCS fixturing.

- Table Size: Length 110"/2800mm x Width 63"/1600mm

- Measuring Envelope: Length 94.5"/2400mm x Width 55"/1400mm x Height 59"/1500mm

- Repeatability: 0.00012"/0.003mm

- Volumetric Accuracy: 0.00094"/0.024mm

- Linear Accuracy: 0.00016"/0.004mm

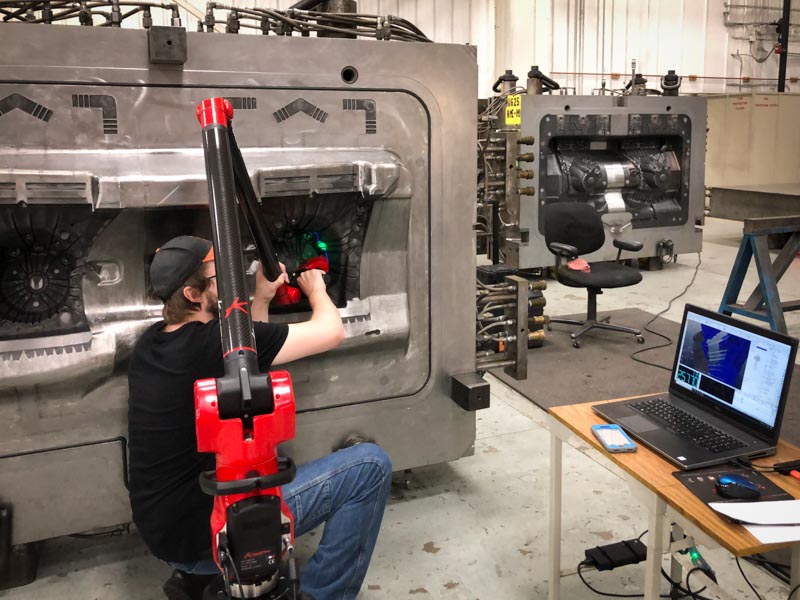

Kreon Ace Measuring Arm with Skyline 3D Scanner

Also known as a portable CMM, the Ace measuring arm provides precision measurement and validation on any size part, virtually anywhere. Our measuring arm is also equipped with the Skyline 3D scanner, to quickly collect 3D surface maps for mold and part validation, as well as reverse engineering.

Also known as a portable CMM, the Ace measuring arm provides precision measurement and validation on any size part, virtually anywhere. Our measuring arm is also equipped with the Skyline 3D scanner, to quickly collect 3D surface maps for mold and part validation, as well as reverse engineering.

A finished casting is being validated to ensure accurate shrink and true dimensions.

A finished casting is being validated to ensure accurate shrink and true dimensions.

- 7 axis measuring arm

- Contact probe for precision point data collection

- Skyline Wide Laser Scanner for high-speed surface collection

- Up to 600,000 points-per-second data collection rate

- Accuracy to 0.00035"/0.009mm

FCS Fixturing

All machining centers and validation equipment utilizes FCS fixturing as seen in the CMM photo above. FCS fixturing speeds machine setups, improves accuracy, and reduces mistakes.

Software Capabilities

Metrolog X4 software is capable of accurately measuring and dimensioning features of all types of machine parts, models, and molds. Reports can consist of simple linear measurements, or in terms of geometric dimensioning and tolerancing, such as location, true position, distance, angularity, concentricity, roundness, straightness, flatness, perpendicularity, parallelism, runout, and surface profile. It also has the capability of importing CAD data into a program and comparing the measured dimensions of a work piece to its CAD design.

The Kreon Scanner is portable, allowing validation of large dies on the floor or even in machines.

The Kreon Scanner is portable, allowing validation of large dies on the floor or even in machines.Metrology Department Information

General Die & Engineering CMM technicians create customized layout reports which are tailored to each client's needs. This includes reports relating to part designs, mold designs, CAD data, and before / after information for design changes, repair work, etc.

Validation Department Contact

Romen Haglund

- Contract CMM & Scanning Services

Phone (616) 871-1464