Process-Driven Scheduling System

At General Die & Engineering, we are process-driven. Over the years we have developed a system for the design and manufacturing of reliable, high-quality molds and dies. Our process starts with close collaboration with our clients to ensure we effectively fulfill all requirements while developing a cost-effective solution. At the heart of this is careful attention to design for manufacturability, both for our molds and dies, and for our clients' end products. Our thorough review of each project at completion assures continuous improvement in our process, as well as each end-product we deliver.

- We use an internal machining schedule, “MS Project Master Timeline” for all CNC machines including any sub-contractors if needed.

- General Die & Engineering utilizes Microsoft Project for all planning and tracking of tool builds, detailing Engineering, to all operation in the cavities, building of the mold base, to final assembly.

- We are also capable of sampling all plastic injection molds at a nearby sampling facility. We also have the capability of sampling die cast dies at an outside facility.

Machining Cutterpaths

All cutterpath programming is done right at each CNC machine utilizing Work NC software.

Our machining departments work in tandem with our Engineering department for a smooth data flow from design to steel. Our quality control system assures the most latest, most up-to-date released design data is being used in the programming for CNC machines.

CMM Inspection

- Critical electrodes prior to EDM

- Cavity steel upon completion of build

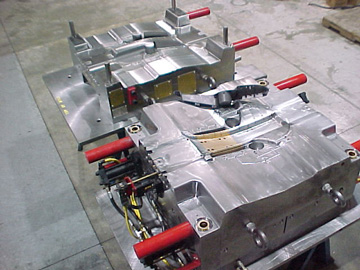

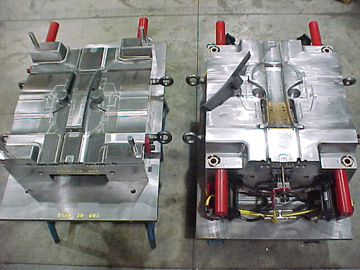

Plastic Injection Molds

Specializing in highly visible parts both interior and exterior. Widely known for building difficult injection molds with multiple actions and diamond finished cavities. One of the foundations of our multi faceted tooling service we offer here at General Die & Engineering.

Plastic Injection Mold Details

Regardless of the size or complexity of your part, we have the capability and experience to build your tooling. Whether it's a large fender liner or small intricate mold, simple open/close or multiple slides/lifter/retractors, General Die & Engineering can supply you with the robust tooling that your production requirements demand.

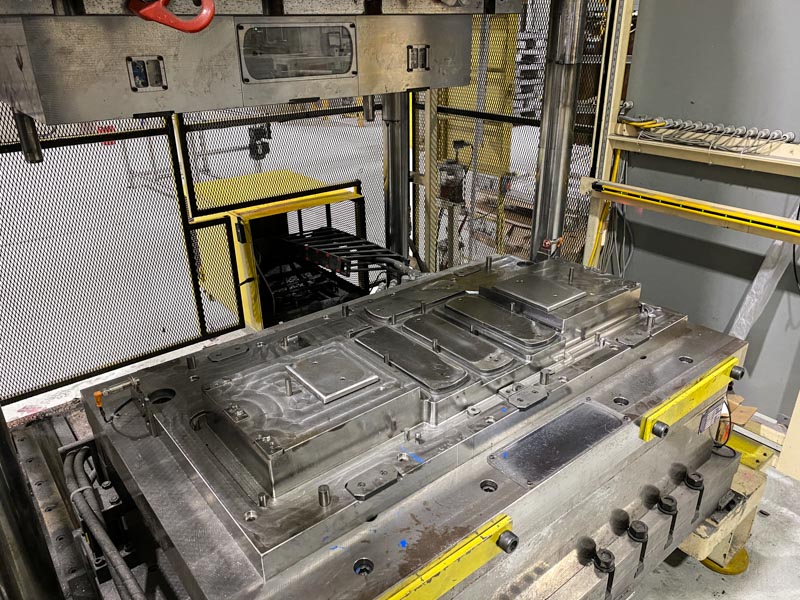

Rear wheel liner mold

Rear wheel liner mold

Rear wheel liner mold

Rear wheel liner mold

Cup holder armrest

Cup holder armrest

Cup holder armrest

Cup holder armrest

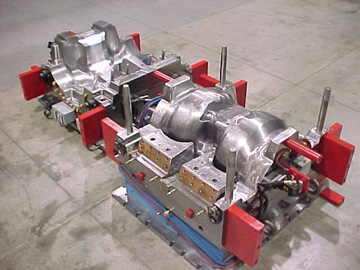

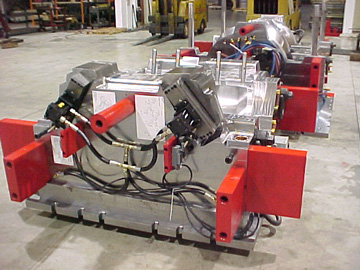

Die Cast Dies

Specializing in magnesium and aluminum die cast dies built to your specifications and standards. GDE has long been an industry leader, fulfilling todays timing and quality needs to meet expectations in making lighter and more fuel efficient cars of tomorrow.

Die Cast Die Details

2010 Pace Award Winning Die Design

2010 Pace Award Winning Die Design

General Die & Engineering has always been, and continues to be, on the leading edge of the die cast tooling industry.

With today's deadlines getting shorter and shorter, you need a tooling supplier who can deliver a robust quality tool in more compressed timeframes. General Die & Engineering has a long history of meeting and exceeding our customers expectations in that regard. Our quality system allows us to record and track any and all changes during the tool build process, to insure your tool meets your precise expectations. Our knowledgeable engineering and design staff are ready to take your data and their experience to design a tool that meets your standards, in a timely fashion.

Industry First

In 2003, General Die & Engineering was the industry leader in designing and building the first 2 cavity die cast magnesium instrument panel tool in the world.

In 2003, General Die & Engineering was the industry leader in designing and building the first 2 cavity die cast magnesium instrument panel tool in the world.

Largest Dies

The magnesium tailgate inner is the largest die cast magnesium closure panel globally. It not only saves substantial weight but it also functions as the primary structural load carrying component of the liftgate assembly meeting stringent crash performance requirements, integrates six separate parts into one inner panel casting, allows for increased passenger headroom, is 100% recyclable and meets the acceptance criteria for Class A die cast surfaces.

In 2008 we designed and built another first. This time it was a liftgate. The entire part cast in a single tool, just one of our challenges was to overcome 3 million pounds of shot pressure in a self locking tool.

In 2008 we designed and built another first. This time it was a liftgate. The entire part cast in a single tool, just one of our challenges was to overcome 3 million pounds of shot pressure in a self locking tool.

Giga Press Tooling

Always looking toward the future, General Die & Engineering is investing resources in tooling for the Giga Press. Giga Press die casting is the most recent advance in aluminum die casting. Currently, Tesla has invested in four Giga Press machines manufactured by IDRA Group for their Model Y automobile.

These massive die casting machines range in size from 5,600 ton to 8,000 ton. They are the largest high pressure die casting machines in the world. A single machine weighs almost 1 million pounds. These machines take a 180 pound shot of molten aluminum and cycle into a complete part in 90 seconds. A single machine can produce 1,000 aluminum die casting per day. (source: Wikipedia)

Die Casting Machine #2 (DCM2) Giga Press during assembly at Tesla Factory in Fremont. The open space in the middle between the compression plattens holds the die casting mold halves, and separates apart to allow removal of the completed casting using a robot.

Die Casting Machine #2 (DCM2) Giga Press during assembly at Tesla Factory in Fremont. The open space in the middle between the compression plattens holds the die casting mold halves, and separates apart to allow removal of the completed casting using a robot.

Photo Credit: Gabeincal, CC BY 3.0, via Wikimedia Commons

Die Cast Coining/Straightening Dies

General Die & Engineering is the domestic industry leader with the most experience, 8-years, in building coining/straightening dies for the die cast structural industry.

Coining Die Details

One-directional with no actions

Multi-directional with actions

General Die and Engineering is the domestic industry leader with the most experience, 8-years, in design, engineering, and manufacturing coining/straightening dies for the die cast structural industry.

Coining/straightening dies play an essential role in precision structural die casting to realign parts back to net or near net shape. They are needed to overcome warp issues that occur during the casting process or after parts been stress relieved or heat treated.

Manufacturing Equipment and Capabilities

General Die & Engineering is equipped with a wide array of machinery to handle the demanding needs of today's high-technology die casting marketplace. From large capacity horizontal and vertical machining centers, to dynamic high speed machines, precision EDM machinery, and a full compliment of support equipment, we have the right equipment for the job.

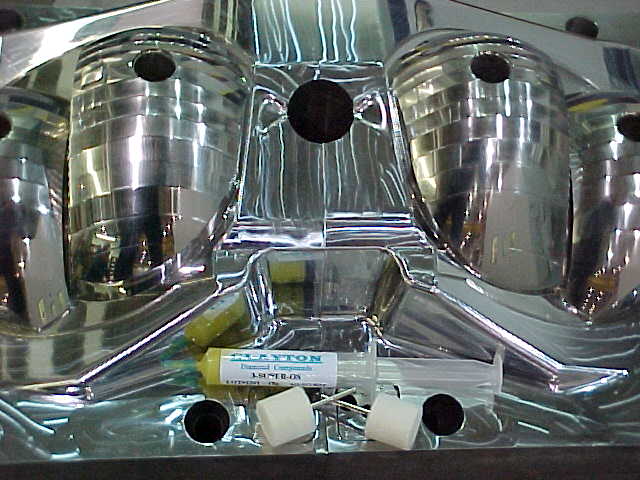

Polishing

General Die & Engineering provides in-house mold and die polishing. Diamond polishing is performed in an isolated room to prevent contamination. Polishing in-house assures you of fast, on-time deliveries.

Polishing

General Die & Engineering has skilled polishers that are capable of providing any finish you require, from a die cast draw finish to an SPE-1 or SPE-2 diamond finish.

Fitting and Full Die Spotting

We "hot spot" die cast dies at nominal operating temperatures to mimic thermal expansion differences that occur in production. You get a better, more accurate part with less flash in the part production environment.

General Die & Engineering fits dies at nominal operating temperature for higher accuracy.

General Die & Engineering fits dies at nominal operating temperature for higher accuracy.

Manufacturing Department Contacts

Craig Karman, V.P. of Manufacturing

- Manufacturing Oversight

- Quality Assurance

- Scheduling and On-time Delivery

Phone (616) 871-1444

Tim Blake, Assistant Shop Foreman

- Die Cast Repair

- Plastic Injection Repair

- Receiving Services for Global-Sourced Tooling

Phone (616) 871-1450